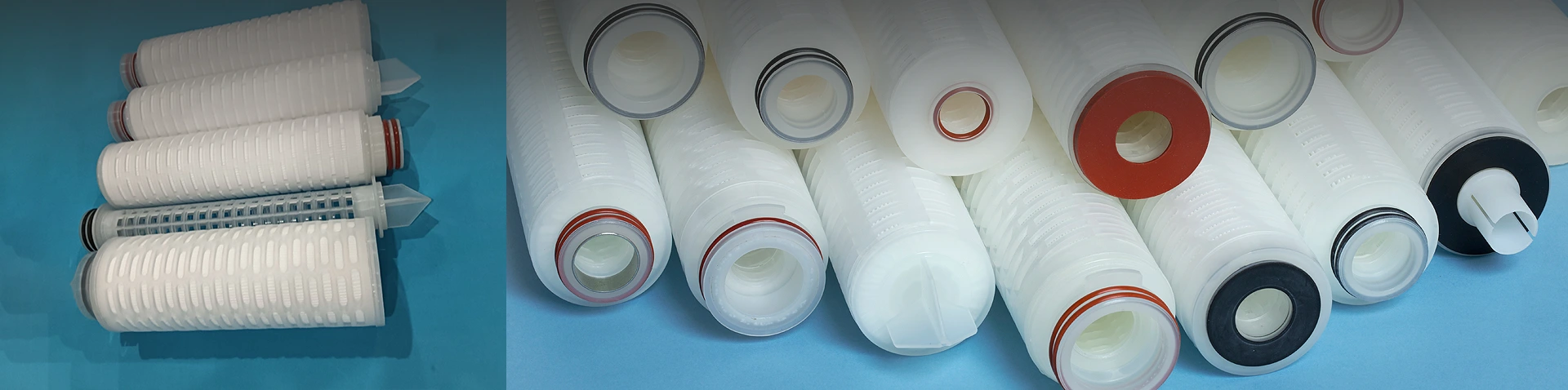

General Filtration PTFE Mini Filter Cartridge

Biosep Filtration provides high accurate OEM service. General Filtration PTFE Mini Filter Cartridges are made with absolute precision PTFE membranes, and each cartridge is 100% integrity tested in the manufacturing process. Each cartridge is 100% integrity tested in the manufacturing process to ensure effective bacterial removal and long service life. The natural hydrophobic properties of PTFE ensure high gas flux and filtration capacity in high humidity conditions. The inherent chemical inertness of PTFE membranes ensures broad chemical compatibility. We offer pore sizes of 0.1µm, 0.2µm, 0.45µm, 1.0µm, 3.0µm, 5.0µm.

Send Inquiry

Biosep Filtration is a manufacturer who has 10 years of experience in producing filter cartridges, and a supplier who has the ability to design products and production lines independently. Biosep Filtration has been supplying filter cartridges made of various materials including but not limited to PP, PES, PTFE, Nylon, etc. to clients from all over the world for a long-term period of time.

The General Filtration PTFE Mini Filter Cartridges are made from a single layer of hydrophilic PTFE membranes and each cartridge is 100% integrity tested during the manufacturing process to ensure effective removal of fine particles and harmful microorganisms from liquids and stability of product performance. Each cartridge is 100% integrity tested in the manufacturing process to ensure effective removal of fine particles and harmful microorganisms from liquids, as well as product performance stability. The cartridges offer broad chemical compatibility. High throughput and long service life. We offer pore sizes of 0.1µm, 0.2µm, 0.45µm, 1.0µm, 3.0µm, 5.0µm.

Typical Applications

·Compressed air

·Pressurized gases

·Tank ventilation

·Chemicals

·Solvents

Filter Area:

H: 550cm^2 S: 1100cm^2

D: 1800cm^2 L: 2500cm^2

Capsule Integrity

| Pore size | Bubble Point/IPA |

| 0.1um | 1.7barg |

| 0.2um | 1.1barg |

| 0.45um | 0.6barg |

| 1.0um | 0.4barg |

| 3.0um | 0.1barg |

| 5.0um | 0.07barg |

Food Safety Compliance

Materials of construction comply with FDA regulations for food and beverage contact use as detailed in the US Code of Federal Regulations,21CFR.

Materials used to produce filter media and hardware are safe for use in contact with foodstuffs in accordance with EU Directives 10/2011

Maximum operating parameters

Differential Pressure

·Forward 80 psid (5.5 barg) at 20℃(68 °F)

·Reverse 40 psid (3.1 barg) at 44 ℃(75°℉)

Operating Temperature 82 ℃(180 °℉) at 10 psid(6.9 barg)

Recommended Changeout Pressure:35psid(2.4barg)

Toxicity

All components meet the specifications for biological safety per USP Class VI-121'C for plastics.

Construction Materials

Filter Membrane:ePTFE Membrane

Media Support: Polypropylene

End Caps: Polypropylene with embedded 316 ring

Inner Core: SUS 316L perforated core

Outer Cage: Polypropylene

Sealing Method:Thermal Bonding

O-rings: Buna, Viton(or FKM), EP, Silicone,Encapsulated Silicone,Encapsulated Viton (or FKM)

Order:

|

PORE SIZE |

AREA |

ENDCAPS |

SEAL |

CONNECTION SUPPORT |

|

001=0.1um 002=0.2um 004=0.45um 006=0.65um 010=1.0um

|

H=500cm^2 S=1100cm^2 D=1800cm^2 L=2500cm^2

|

A=116 w/o locking groove B=116 w/ locking groove C=116 w/locking groove,ss ring D=118 double o-ring E=118 w/ short lugs (Pall replacement) F=118 w/longlugs(Sartorious replacement) G=1/2"NPT threaded H=123 double o-ring I= 126 double o-ring J= 1"TC K=80mm skirting L=1/2"TC M=1/2"BSPT N=123 double o-ring O=AS116(Pall replacement) P=AS116 (Parker replacement) Q=1/2"BSPP |

B=Buna-N E=EPDM S=Silicone V=Viton

|

S= With SS reinfocement

|